The manufacturing sector faces a significant skills gap in its workforce. In a recent survey, Gartner Research found that 57% of manufacturing leaders report a lack of skilled workers to support smart manufacturing initiatives. If more than half of the industry struggles to find existing talent, what’s the only option? To develop it yourself.

As automation, digital processes, and new technologies reshape the industry, companies must equip their workforce with the tools to onboard, reskill, and upskill effectively. But manufacturing comes with unique workforce development challenges. Large, specialized teams often span distinct roles, products, or facilities. Training this diverse workforce requires adaptable and scalable solutions.

A learning management system (LMS) is the ideal solution for meeting these challenges. It streamlines training in manufacturing, boosts engagement, and simplifies compliance management, ensuring employees and partners are prepared with training that’s as dynamic as the industry itself.

This article explores how an AI-powered LMS for manufacturing can close the skills gap, support workforce development, and drive meaningful business results.

What are the biggest L&D challenges in the manufacturing industry?

Workforce development in manufacturing is no small task. The industry’s work environments are diverse, technical, and dynamic. Here are some of the most pressing obstacles faced by the industry’s learning and development (L&D) teams:

Technical complexity

Manufacturing processes often involve highly technical concepts and procedures, making it difficult to create a single set of learning content. Employees also bring different ages, backgrounds, and education levels to the table. To bridge the gap, training programs must break down complex topics into clear, actionable instructions so workers at all skill levels can benefit.

Constantly evolving regulations

Staying up to date with industry and governmental regulatory standards is an ongoing challenge for L&D teams. By the time you’ve updated one course, new legislation might make it outdated. For L&D teams, staying ahead requires agility in course creation.

A diverse workforce

Manufacturing companies are a blend of skill levels, ages, cultural backgrounds, and education levels. Designing understandable, engaging, and relevant training in manufacturing for such a diverse group requires a thoughtful, inclusive approach to ensure no one is left behind.

High-risk work environments

Delivering effective training in environments where physical safety is a top priority adds another layer of complexity. Unlike other industries, the stakes are high—serious injuries or fatalities can result from insufficient training. Programs must prepare employees for the practical realities of high-risk work settings where dangerous machinery and robotics are used so they can apply their knowledge to prevent accidents.

Employee engagement

Dry safety and compliance training has historically been the norm in manufacturing, but it doesn’t have to be. Engaging employees in key topics like safety and compliance training requires creativity to make the content memorable and relatable.

Measuring training effectiveness

Tracking whether employees retain and apply their training in day-to-day tasks is essential but difficult to measure. L&D teams must evaluate training programs for their impact on performance, safety, and compliance.

5 key ways a manufacturing LMS engages learners and improves safety

A manufacturing-specific LMS should offer tools that make learning accessible, interactive, and effective. From creating engaging safety training to tracking compliance, an LMS for manufacturing keeps employees informed and motivated to apply their knowledge on the job. Here are five key ways an LMS enhances engagement and safety in the manufacturing environment:

1. Industry-specific curated content

An LMS stocked with industry-specific curated content keeps your team ready for today’s challenges while building the skills needed for tomorrow. Industry-specific libraries offer cost-effective and engaging resources, providing high-quality learning experiences that keep your workforce prepared and ahead of the curve.

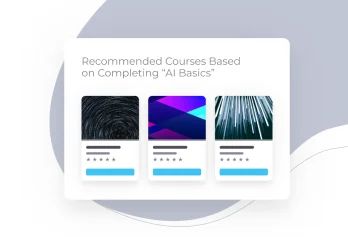

2. Personalized L&D management with AI

Employees who feel empowered to develop new skills are more engaged in their roles and more likely to stay and grow along with your organization. And, of course, organizations with well-trained teams that are knowledgeable in their job functions will be more productive. An AI-powered LMS can customize training programs based on predefined competencies and individual needs—removing the guesswork for L&D teams.

3. Improved reporting capabilities

With customizable, digital reporting tools, you can easily create reports tailored to your organization’s specific needs. Whether you need scheduled reports for routine updates or ad hoc business intelligence reports, your LMS for manufacturing can provide the learner and program data that matters most.

Reporting tools also support your regulatory compliance efforts by tracking and recording learner progress and course completion. You can measure the impact of corporate training in manufacturing programs by linking them to your organization’s relevant KPIs, measuring the cost-effectiveness of your learning initiatives.

To support data-driven decisions, intelligent dashboards and visualization tools identify trends, uncover opportunities for improvement, and optimize your learning programs. By using new data-driven insights, you can continuously refine your training in manufacturing strategy.

4. Integrating other business management systems

Integrating your LMS with other systems streamlines operations and eliminates manual errors. Built-in integrations simplify data exchange between your business systems, reducing the need for IT involvement.

For L&D teams, the most important integration to consider is with your human capital management (HCM) platform. Syncing LMS and HCM platforms can simplify tracking what resources you have available to your business and how best to develop them. If your L&D team manages partner and customer learning, you’ll benefit from CRM integration.

5. Simplified cross-skilling and talent development

Cross-skill development for employees helps organizations increase their operational flexibility. Workers can more easily step into distinct roles. That minimizes downtime and enhances safety because cross-trained employees can spot risks and compliance issues across different work units. Cross-skilling also prepares workers for new technologies used elsewhere in your business that might come to their work unit in the future.

Aside from the productivity gains, these initiatives demonstrate your commitment to employee growth. That has been shown to boost retention and morale, which leads to a positive cycle of engagement and development.

Which metrics should I track in learning and development in a manufacturing program?

Monitoring key metrics is key to evaluate both learner engagement and outcomes, ensuring your corporate training programs in manufacturing deliver real impact. Here are some of the most important metrics to track, along with examples of their application.

Learning retention rate

Learning retention rate measures how well employees retain the information presented in the training. This can be assessed through follow-up quizzes or on-the-job performance evaluations. For example, if workers struggle to recall key procedures during safety drills, they may need more frequent reinforcement or microlearning refreshers.

Course completion rate

Completion rate tracks the percentage of learners who finish a course. A low completion rate indicates that the content isn’t engaging enough, or the format doesn’t fit into employees’ schedules. For example, if 60% of learners drop off midway through a safety course, it might be time to introduce interactive elements like quizzes or gamification to keep them engaged.

Learner satisfaction

Learner satisfaction measures participants' feelings about the training program, typically through post-course surveys. Positive satisfaction scores indicate that the training meets employee expectations and needs. But, for instance, if a compliance module consistently receives low ratings, it might need clearer instructions, updated content, or a more engaging delivery method.

Training ROI

Training ROI evaluates the return on investment of your manufacturing eLearning programs. Compare the cost of training with measurable benefits like increased productivity or reduced errors. For instance, if a $5,000 investment in cross-skilling reduces downtime by 20% annually for a $50,000 FTE team, the program can be considered successful. Monitoring ROI ensures your manufacturing eLearning initiatives align with business goals.

Better prepare your manufacturing workforce for the future

Learning isn’t just about checking boxes, finishing tests, and meeting minimum requirements. It’s a key driver of growth and innovation. For manufacturing organizations, look beyond basic compliance and competency training and consider how an LMS can expand its impact.

Absorb LMS empowers organizations to maximize the impact of their L&D programs. Delivering meaningful and engaging learning experiences drives business productivity and helps achieve training goals with measurable results. Whether you’re training internal employees or external partners, the platform is designed to prioritize the ultimate goal of learning—outcomes. With a deep understanding of learners' challenges and how to overcome them, Absorb LMS supports organizations in fostering growth and success through effective training.